Description

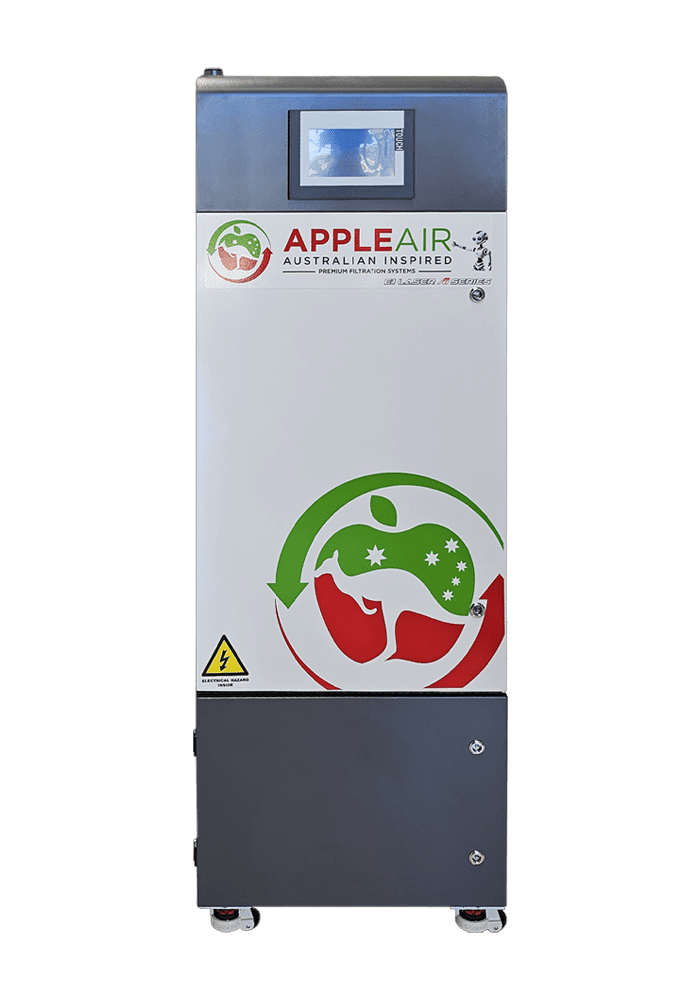

Our 906Ai S2 Laser Series purifier is designed to effectively filter laser engraving & cutting dust, fumes & Odor. This machine utilizes 5 unique 6 individual filtering technologies for maximum efficiency.

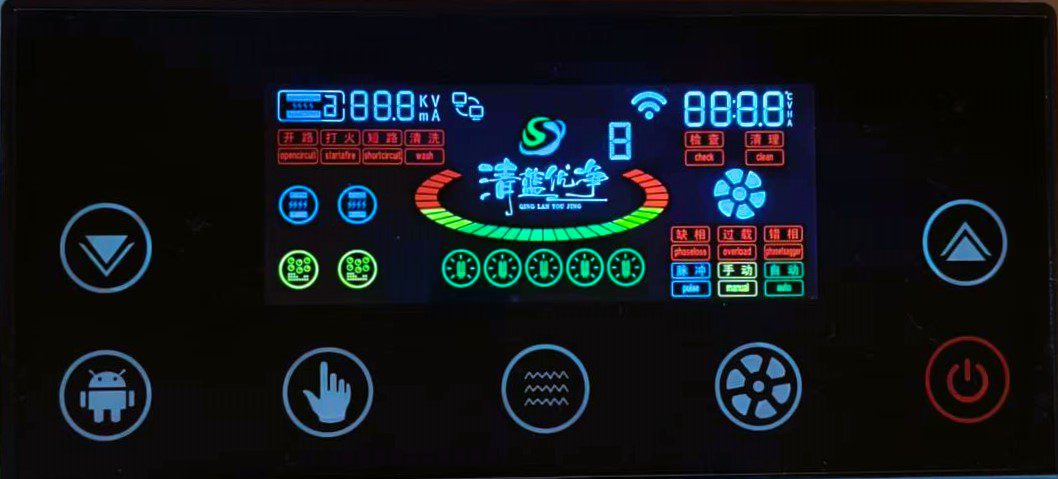

Equipped with a multi function intelligent touch screen control system, this machine looks after itself. It reports any fault condition so you know when to clean the filters.

The filtration systems is suitable for cutting and engraving various non-metal materials such as (acrylic, ABS, plywood, wood, MDF, leather, tumblers, Metal Paste compounds, laser inks, fabric etc.) to name just a few.

Our low replacement cost filters make this the most affordable filtration system on the market to date. The unique electrostatic filter simply needs washing when dirty not replacing saving you thousands in consumable costs. Remote start available.

Filters included and available to purchase:

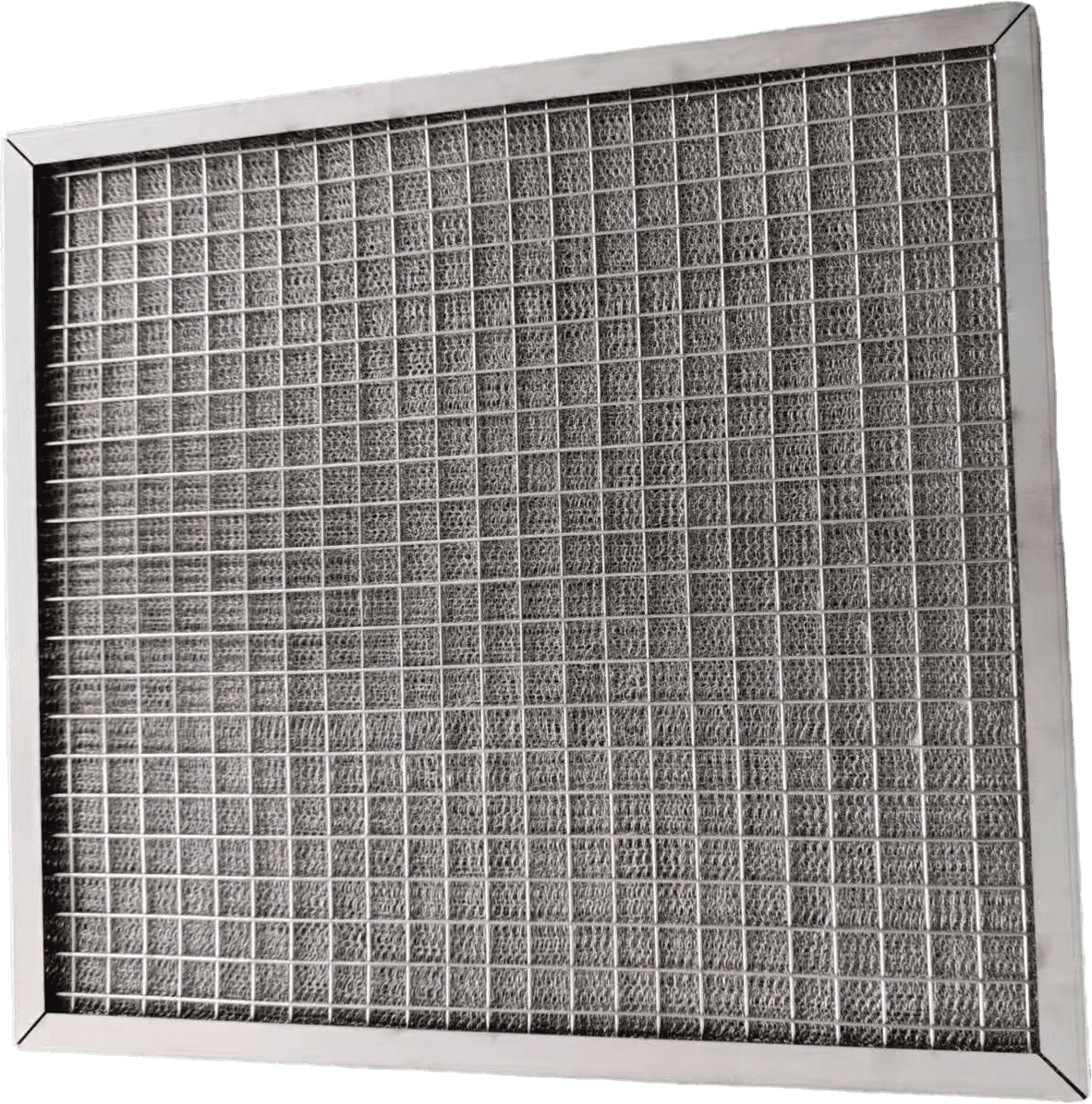

First Layer – Metal washable filter – No need to replace just wash

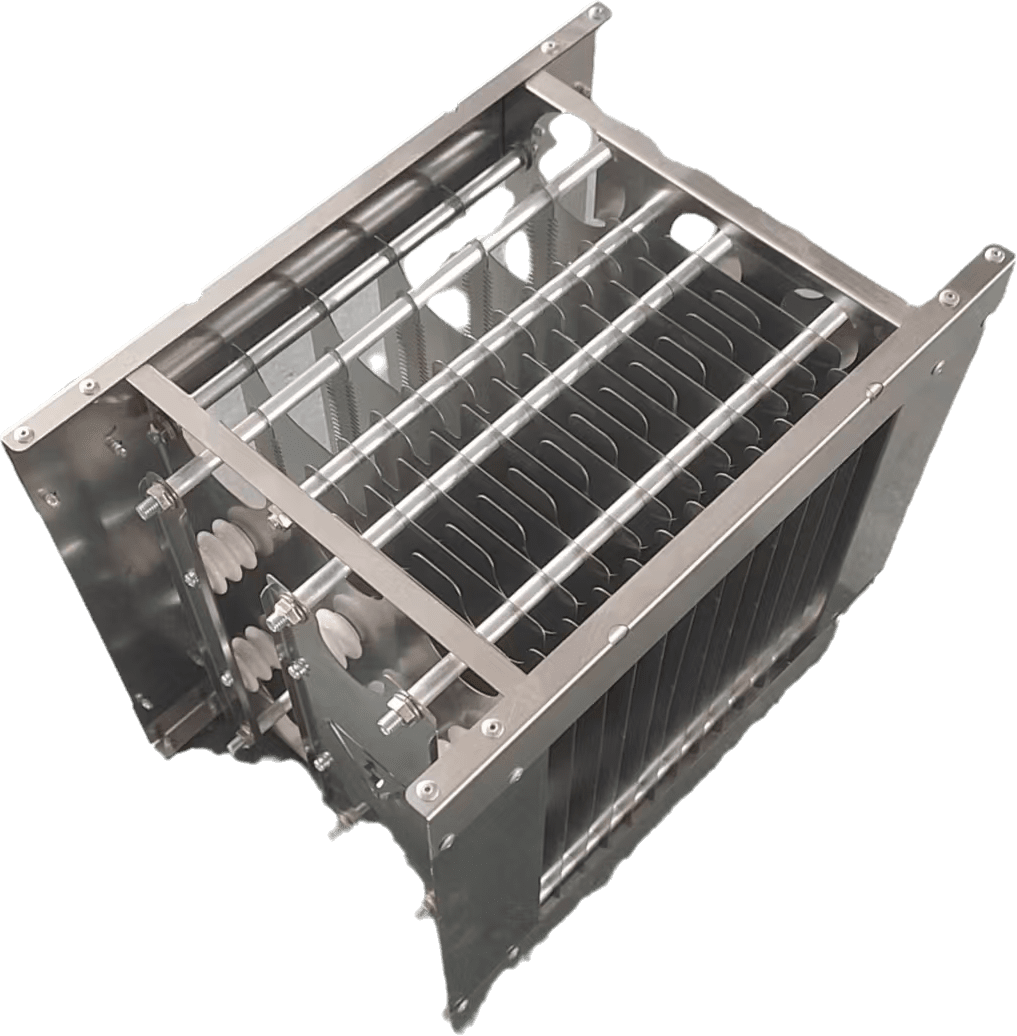

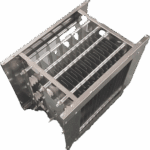

Second Layer – Electrostatic Electronic Filter – No need to replace just wash

Third Layer – 3 x UV Light Electronic Filters – Expected life 5 years

Fourth Layer – Active Carbon Filter – Expected Life 1 year

- How it works:Our Electrostatic precipitation (ESP) systems, used for air purification, and are enhanced by our UV Lamps & Ionization Lamps to combat the potential for ozone formation and other unwanted by-products.

ESPs work by charging particles in the air stream and then attracting them to oppositely charged plates, effectively removing them from the air and are >99% effective.

- Applications:

ESPs are used in various applications, including laser engraving machines, Direct to Fabric Printers, Powder Shakers, air pollution control and indoor air purification just to name a few.

- Ozone Formation:

High-voltage systems in ESPs can produce ozone, which can be a harmful pollutant. Our 5 UV Lamps deal with that Ozone by decomposing the particle.

- UV’s Role:

UV lamps can be integrated into ESP systems to decompose ozone and inactivate certain types of particles, enhancing overall air quality.

- Benefits:

- Improved air quality: By removing pollutants, UV-enhanced ESPs can improve indoor air quality.

- Inactivation of pathogens: UV can be used to inactivate viral and bacterial particles, further enhancing safety.

- Ozone decomposition: UV can decompose ozone produced during the ESP process, mitigating potential hazards.

- After the organic gas has passed through the filters, the organic (Odor) gas is decomposed and oxidized by high-energy ultraviolet beam and ozone, so that the organic gas material can be degraded into low molecular compounds, water and carbon dioxide, and then discharged outdoor through the extraction outlet.

After a series of chemical reactions, chemicals such as hydrogen sulphide and methyl alcohol, can be oxidized in a short period of time. At the same time, oxygen ions can destroy the living environment of bacteria in the air and reduce the concentration of indoor bacteria. Charged ions can adsorb suspended particles tens of times of their own weight and settle down by their own weight, so as to remove the suspended colloids in the air and purify the air.

- Improved air quality: By removing pollutants, UV-enhanced ESPs can improve indoor air quality.

Annual Filter Replacement Costs

Based on changing the required filters every 12 months the yearly cost of filters will be $60ex gst

Recommended for:

CO2 laser cutting & Engraving machines with a bed size up to 900mm x 600mm.