Description

Our AA3015-E2 laser cutting & engraving purifier is designed to effectively filter laser engraving & cutting dust, fumes & Odor. This machine utilizes 6 unique – 22 individual filters for maximum efficiency with a variable speed fan control system. The filtration systems is suitable for cutting and engraving various non-metal materials such as (acrylic, ABS, plywood, wood, MDF, leather, tumblers, Metal Paste compounds, laser inks, fabric etc.) to name just a few. Our low-cost filters make this the most affordable filtration system on the market to date. The unique electrostatic filter simply needs washing when dirty not replacing saving you thousands in consumable costs. Remote start available. We have fitted a 2.2Kw extraction fan to this system and provided dual inlets spigots.

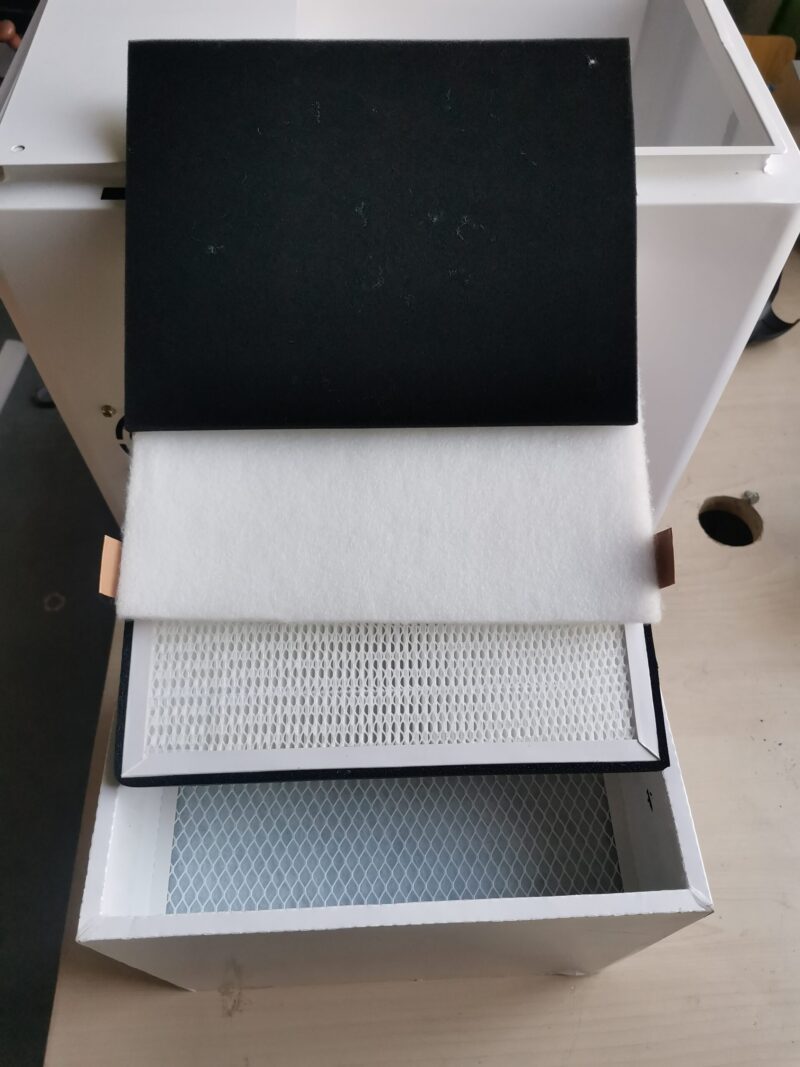

Filters included and available to purchase:

First Layer – Triple Dust collection Filters – Expected life is 1 year

Second Layer – Secondary Fine Particle Filter – Expected life is 1 year

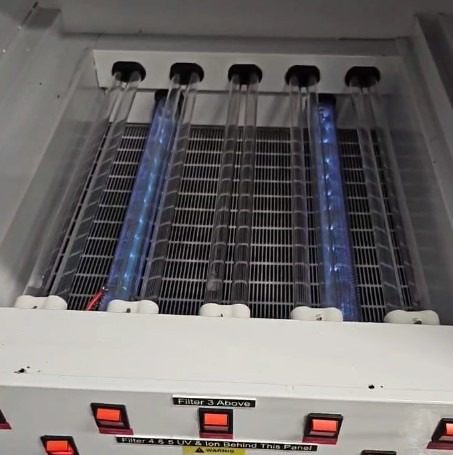

Third Layer – Electrostatic Electronic Filter – No need to replace just wash

Fourth Layer – 5 x Electronic UV Light Filters – Expected life 3-5 years

Fifth Layer – 2 x Electronic Ion Filters – Expected Life 3-5 year

Sixth Layer – 9 x Active Carbon Filters – Expected Life 1 year

Seventh Layer – 1 x Carbon Filter – Expected Life 1 year

Eights Layer – 1 x Active Carbon Filter Draw – Expected Life 1 year

How it works:

High energy and high ozone ultraviolet beam is used to decompose oxygen molecules in the air to produce free oxygen, i.e. active oxygen. Due to the imbalance of positive and negative electrons carried by free oxygen, it is necessary to combine with oxygen molecules to produce ozone. It is well known that ozone has a strong oxidation effect on organic matters and has an immediate effect on the removal of organic gases and other pungent Odors.

After the organic gas has passed through the filters, the organic (Odor) gas is decomposed and oxidized by high-energy ultraviolet beam and ozone, so that the organic gas material can be degraded into low molecular compounds, water and carbon dioxide, and then discharged outdoor through the extraction outlet.

After a series of chemical reactions, chemicals such as hydrogen sulphide and methyl alcohol, can be oxidized in a short period of time. At the same time, oxygen ions can destroy the living environment of bacteria in the air and reduce the concentration of indoor bacteria. Charged ions can adsorb suspended particles tens of times of their own weight and settle down by their own weight, so as to remove the suspended colloids in the air and purify the air.

Recommended for:

CO2 laser cutting machines with a bed from 900mm x 600mm up to 2500mm x 1300mm.

-scaled-800x600.jpg)

-scaled-150x113.jpg)